When it comes to protective equipment, understanding the standards that govern their safety is key. EN 407:2020 specifies the requirements and testing methods for gloves designed to shield against thermal risks like heat and fire. Here’s a breakdown of the standard, its icons, and the performance levels that guide you in choosing the right gloves for high-heat or flame-prone environments.

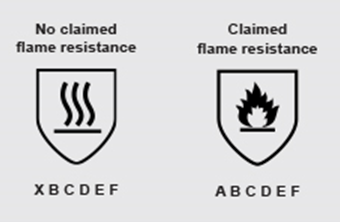

Key Icons: Flame Resistance vs. Non-Flame Resistance

EN 407:2020 introduces two pictograms, distinguishing between gloves designed for flame-resistant versus non-flame-resistant applications. Importantly, these icons cannot be used together, ensuring clarity on the gloves’ specific capabilities.

The numbers shown with each icon represent performance levels for each of the tests, with higher numbers indicating better protection. If an “X” appears, it means no protection level is claimed for that test.

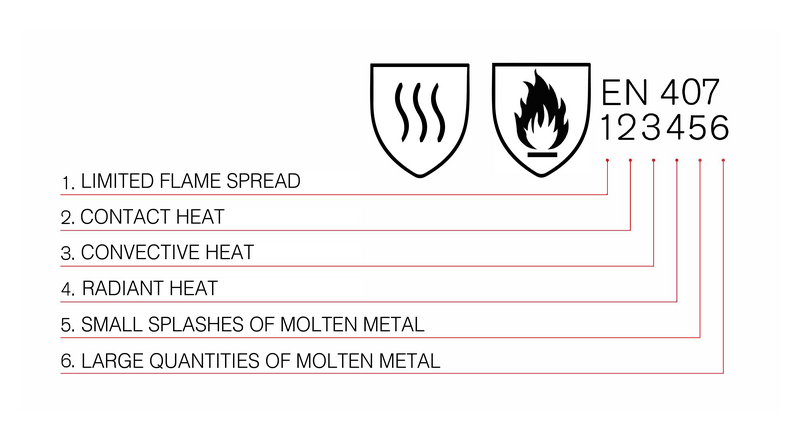

Performance Tests and Levels Explained

EN 407:2020 outlines six key tests to evaluate a glove’s thermal resistance. Each test assesses a specific kind of heat exposure, with performance levels indicating protection strength.

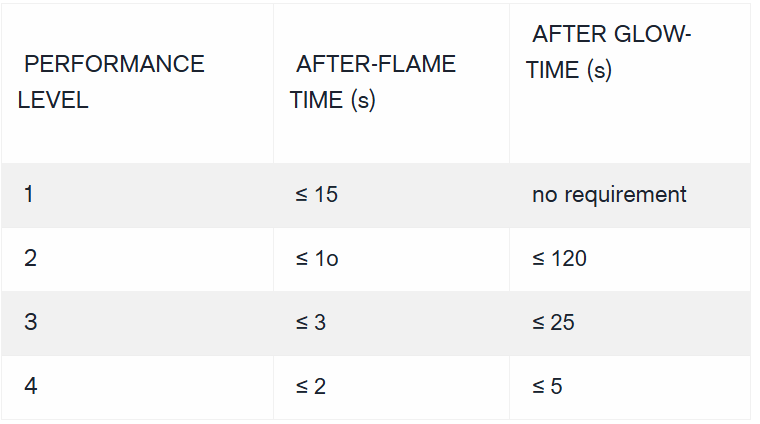

1. Limited Flame Spread

This test determines the glove’s ability to protect against short contact with flames. Gloves don’t need to be non-flammable, but they must slow combustion, allowing the wearer to react and remove the glove safely. The glove is exposed to a test burner, and both the time the glove burns after the flame is removed (after-flame time) and any residual glow (after-glow time) are recorded.

- Performance Levels:

- Level 1: After-flame time ≤ 15s

- Level 2: After-flame time ≤ 10s, After-glow ≤ 120s

- Level 3: After-flame time ≤ 3s, After-glow ≤ 25s

- Level 4: After-flame time ≤ 2s, After-glow ≤ 5s

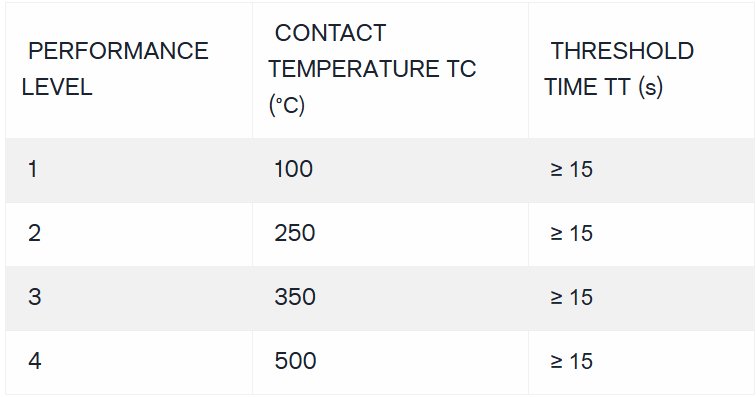

2. Contact Heat

When holding hot objects, heat can transfer through the glove to the skin. This test measures the time it takes for the glove interior to warm by 10°C when exposed to temperatures between 100°C and 500°C. To pass, gloves must delay this temperature rise by at least 15 seconds.

- Performance Levels:

- Level 1: Contact temperature 100°C

- Level 2: 250°C

- Level 3: 350°C

- Level 4: 500°C

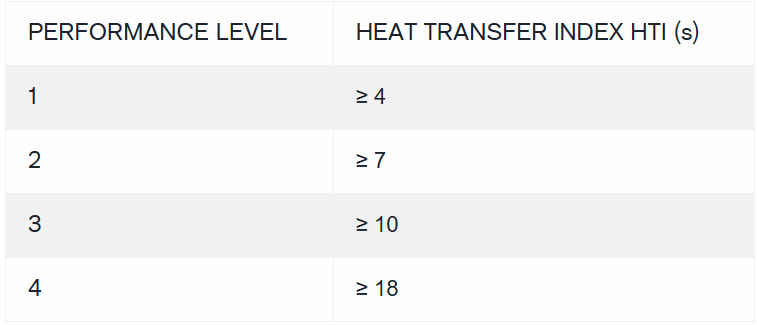

3. Convective Heat

This test measures heat transferred by air or fluids around the glove. The sample is exposed to a heat source, and the time taken for the inside of the glove to warm by 24°C is recorded.

- Performance Levels:

- Level 1: ≥ 4 seconds

- Level 2: ≥ 7 seconds

- Level 3: ≥ 10 seconds

- Level 4: ≥ 18 seconds

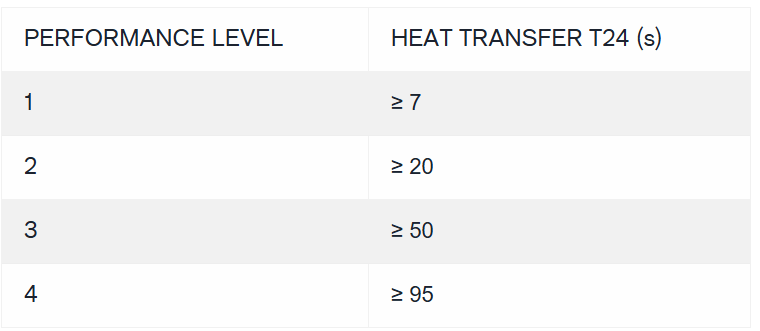

4. Radiant Heat

Invisible yet intense, radiant heat can cause burns even without direct contact. This test measures how long it takes for radiant heat to raise the temperature by 2.5 kW/m².

- Performance Levels:

- Level 1: ≥ 7 seconds

- Level 2: ≥ 20 seconds

- Level 3: ≥ 50 seconds

- Level 4: ≥ 95 seconds

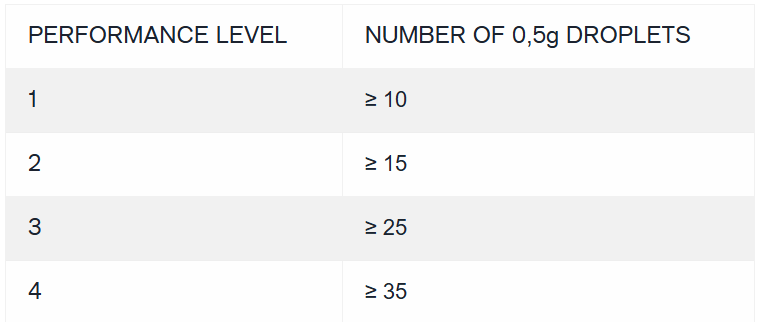

5. Small Splashes of Molten Metal

This test assesses the glove’s resilience to small molten metal splashes, commonly encountered in metalworking. Gloves that perform well allow droplets to roll off, preventing excessive contact time and temperature rise.

- Performance Levels:

- Level 1: 10 droplets

- Level 2: 15 droplets

- Level 3: 25 droplets

- Level 4: 35 droplets

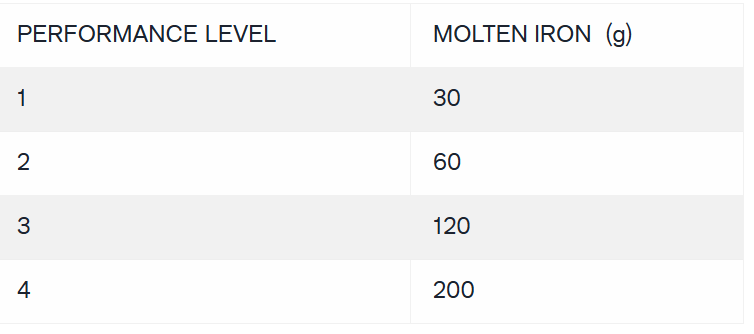

6. Large Quantities of Molten Metal

To test gloves against larger metal splashes, molten iron is poured onto the glove material, and damage to a PVC film beneath is measured. Gloves must be designed to prevent molten metal from collecting in folds or seams, which could ignite or damage the gloves.

- Performance Levels:

- Level 1: 30g

- Level 2: 60g

- Level 3: 120g

- Level 4: 200g

Conclusion

Choosing the right thermal protective glove requires understanding each test and its respective protection levels. EN 407:2020 provides a clear guide to help you assess gloves based on flame spread, contact and convective heat, radiant heat, and resistance to molten metal splashes. Always look for the appropriate performance levels in each category to ensure maximum safety in the intended work environment.