What are Full-Face Respirators?

Full-face respirators are essential safety devices designed to protect the wearer’s entire face from hazardous airborne particles, gases, and chemicals. Unlike half-mask respirators that only cover the nose and mouth, full-face respirators also shield the eyes, providing comprehensive protection against potential irritants. These respirators are equipped with a transparent facepiece, typically made of silicone, rubber, or plastic, and feature integrated filters or cartridges that purify the air before it is inhaled.

When Should You Use Full-Face Respirators?

Full-face respirators are crucial in environments where hazardous substances are present that require a higher level of protection than a half-mask style respirator. In addition, the hazards may cause harm to the eyes and skin around the face.

All respirators have an Assigned Protection Factor (APF) that identifies the upper limit for which a particular style of respirator can be used. When used with a cartridge or particulate filter, a full-face respirator provides an APF of 50, while half-mask respirators have an APF of 10. Powered air purifying respirators (PAPR) with a hood or helmet has an APF of 25. What many people misunderstand is that a full-face respirator offers twice the APF compared to a PAPR. You can find more APF information from the CDC’s NIOSH Respirator Selection Logic publication.

Full-Face Respirators vs Half-Mask Respirators

Full-face respirators are ideal for use in industrial settings, chemical handling, pharmaceutical manufacturing, paint and pesticide spraying, and any situation where complete facial protection is necessary and the APF requirement exceeds 10.

Half-mask respirators on the other hand, are suitable for environments where the eyes do not need protection against gases, vapours, and particles, and for any applications that require an APF of 10. However, remember that you can use a full-face respirator wherever a half-mask is required. More protection is always better!

Full-Face Respirator Applications

Below are some specific examples where full-face respirators are particularly useful:

- Chemical Manufacturing Plants:

In environments where chemical vapours, mists, or splashes are present, full-face respirators provide essential protection. Full-face respirators shield the eyes from harmful exposure while ensuring a broad field of vision, which is crucial for safety and operational efficiency in these settings. - Pharmaceutical Production:

Pharmaceutical manufacturing often involves the handling of potent compounds that be hazardous if inhaled or when coming into contact with the skin or eyes. - Firefighting and Emergency Response:

First responders and firefighters face environments filled with smoke, toxic gases, and particulate matter. Full-face respirators can be used where the application does not require a self-contained breathing apparatus (SCBA).

Note: Full-face respirators are not to be worn in IDLH (Immediately Dangerous to Life & Health) situation. Self-contained breathing apparatus should be worn in these environments. - Painting and Sandblasting Operations:

Painting and sandblasting operations generate high levels of airborne particles and potentially harmful vapours. Full-face respirators are vital to protect against lung and eye irritation.

Note: Be sure to check the concentration of particulate in your environment as air supplied respirators may be required. - Asbestos Removal:

Asbestos removal is a high-risk operation requiring stringent safety measures, including superior respiratory protection. Always look for full-face respirators that ensure an airtight seal and are compatible with various filters to ensure workers are not exposed to asbestos fibers.

Note: Be sure to check the concentration of particulate in your environment as air supplied respirators may be required.

How to Fit Test a Full-Face Respirator

Fit testing is vital to ensure that your respirator properly fits your face. It involves adjusting the straps and positioning the mask to achieve a tight, comfortable seal. Testing should be performed in a controlled environment to ensure no leakage occurs around the mask. Be sure to follow proper fit testing procedures as per the Occupational Safety and Health Administration (OSHA) and/or Canadian Standards Association (CSA) protocols.

- Wearing a Full-Face Respirator with a Beard

Facial hair can compromise the seal of a full-face respirator, potentially allowing hazardous substances to bypass the mask. For effective protection, it is recommended to be clean-shaven when using a respirator. Alternatively, you should follow the NIOSH facial hair recommendations for using a respirator.

Note: Be sure to consult OSHA and/or CSA fit testing protocols when fit testing with facial hair. - Wearing a Full-Face Respirator with Glasses

As wearing regular glasses with a full-face respirator can be challenging due to potential seal disruption, you should look for respirators that offer a prescription lens insert. This ensure that users who require vision correction can still use the respirator safely and effectively.

How to Clean a Full-Face Respirator

Proper maintenance and cleaning are essential for the longevity and effectiveness of any full-face respirator. Below are instructions for cleaning the Comfort-Air® Series 130M full-face respirator:

- Disassemble the respirator, removing any filters, cartridges, or accessories.

- Clean the mask and components with respirator disinfect wipes OR mild soap and warm water, avoiding harsh chemicals that could degrade the materials.

- Thoroughly rinse all parts with clean water.

- Allow all components to air-dry completely in a clean environment before reassembling.

- Inspect the respirator for any signs of damage or wear before and after cleaning, replacing any defective parts immediately.

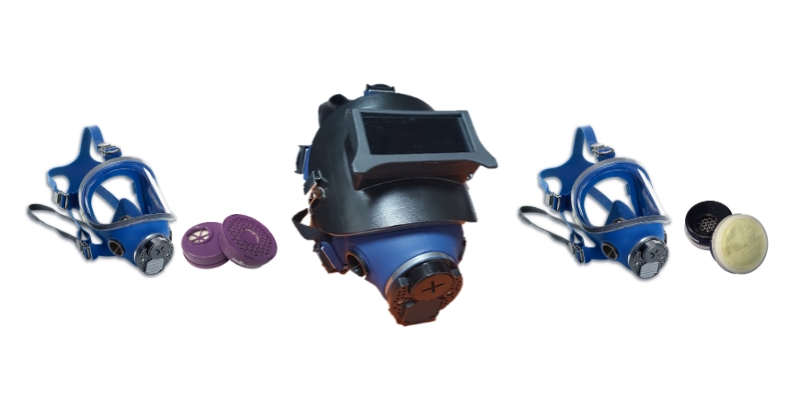

Comfort-Air® Series 130M Full Facepiece Respirator

The Comfort-Air® Series 130M Full Facepiece Respirator from Dentec is made from special composition silicone rubber, ensuring durability, comfort, and ease of maintenance.

The respirator features a large, anti-scratch and anti-fog treated polycarbonate lens, large inhalation valves for reduced breathing resistance, and a metal-speech diaphragm for clear communication. Its 5-point quick-release buckles and “Saf-Twist” cartridge attachment system enhance user convenience, making it an excellent choice for various protective needs.

Choosing the right respirator is crucial for safety in hazardous environments. The Comfort-Air® Series 130M Full Facepiece Respirator offers superior protection, comfort, and versatility, making it an ideal choice for professionals seeking reliable facial protection.

Dentec Safety is a leading manufacturer and distributor of safety products in the North America since 2004. Dentec Safety is dedicated to providing the highest quality safety products and solutions delivering enhanced value and comfort. Our expertise from decades of experience in Industrial Safety and our innovative design technologies have solidified us as thought leaders in the field. Protection and comfort are at the core of everything we do at Dentec. As a leading manufacturer of Safety Solutions, it is our mission to help organizations do the right thing, keep their employees safe and exceed Industry Health & Safety Standard.