It’s common knowledge that there are many workplace hazards in industries like construction, mining, and oil and gas engineering, but did you know that one of the most common and deadly risks is the exposure to Silica Dust?

What is Silica Dust?

Crystalline silica is a mineral that is found in natural materials like clay, sand, gravel, rock and stone. Quartz is the most common form of crystalline silica and in fact it is the second most common surface material accounting for almost 12% by volume of the earth’s crust. Quartz is present in many materials in the construction and landscaping industry such as brick and mortar, concrete, slate, dimensional stone (granite, sandstone) stone aggregate, tile and sand used for blasting. So, the most common materials used in building and landscaping all contain Silica putting those who work with these materials at risk. Silica dust is released from these materials during high-energy operations like sawing, cutting, drilling, chipping, sanding and grinding. These fine particles of crystalline silica release into the air and become a hazardous respirable dust.

Exposure to Silica Dust

Silica dust exposure can occur during common construction tasks such as:

- Masonry saws.

- Grinders.

- Drills.

- Jackhammers and handheld power tools.

- Operating vehicle-mounted chipping tools.

- Operating crushing machines.

- Using heavy equipment for demolition or certain tasks.

Industries where employees are commonly exposed to Silica dust include:

- Mining where large amounts of silica dust is generated during cutting and extracting of stone and become trapped in the ventilating air.

- Cement production and handling (emptying or disposing of bags) and concrete cutting.

- Oil & Gas Engineering.

- Construction.

- Masonry.

- Asphalt manufacturing.

- Demolition.

- Foundry.

- Abrasive Blasting.

- Quarries.

The Risks

Exposure to fine particle of silica has been shown to cause silicosis, a serious and sometimes fatal lung disease, lung cancer, other respiratory diseases, and kidney disease. Review studies in 2020 even showed damage to genetic material in crystalline silica works with adverse health effects because of DNA instability. In 2021, the dangers of silica dust are clear and proper respiratory protection for workers is a non-negotiable thanks to regulations put in place for Canada by the Canadian Centre for Occupational Health and Safety (CCOHS) and for the US by the Occupational Safety and Health Administration (OSHA).

In Canada, the CCOHS is a great place to start for information regarding Silica Dust exposure limits. There are 14 jurisdictions that have their own Occupational Health and Safety legislation:

| Jurisdiction | Regulation | 8 Hour Exposure |

| Federal | Canada Occupational Health and Safety Regulations | Use ACGIH TLVs Quartz and Cristobalite (respirable): 0.025 mg/m3 |

| British Columbia | Occupational Health and Safety Regulation Part 5 Chemical Agents and Biological Agents | Use ACGIH TLVs Quartz and Cristobalite (respirable): 0.025 mg/m3 |

| Alberta | Occupational Health and Safety Code 2009 Part 4 Chemical Hazards, Biological Hazards and Harmful Substances | Cristabolite (respirable): 0.025 mg/m3 Quartz (respirable): 0.025 mg/m3 |

| Saskatchewan | The Occupational Health and Safety Regulations, 1996 | Cristobalite (respirable): 0.05 mg/m3 Quartz (respirable fraction): 0.05 mg/m3 Tripoli, as quartz (respirable): 0.1 mg/m3 |

| Manitoba | Occupational Health and Safety Regulation | Use ACGIH TLVs Quartz and Cristobalite (respirable): 0.025 mg/m3 |

| Ontario | Regulation 833: Control of Exposure to Biological or Chemical Agents | Quartz/Tripoli (respirable): 0.10 mg/m3 Cristobalite (respirable): 0.05 mg/m3 |

| Quebec | Regulation respecting occupational health and safety | Cristobalite: 0.05 mg/m3 Quartz: 0.1 mg/m3 Tridymite: 0.05 mg/m3 Tripoli: 0.1 mg/m3 |

| New Brunswick | General Regulation | Use ACGIH TLVs Quartz and Cristobalite (respirable): 0.025 mg/m3 |

| Nova Scotia | Workplace Health and Safety Regulations | Use ACGIH TLVs Quartz and Cristobalite (respirable): 0.025 mg/m3 |

| Newfoundland and Labrador | Occupational Health and Safety Regulations, 2012 | Use ACGIH TLVs Quartz and Cristobalite (respirable): 0.025 mg/m3 |

| P.E.I. | General Regulations | Use ACGIH TLVs Quartz and Cristobalite (respirable): 0.025 mg/m3 |

| Northwest Territories | Occupational Health and Safety Regulations | Cristobalite (respirable): 0.05 mg/m3 Quartz (respirable): 0.05 mg/m3 Tripoli, as quartz: 0.1 mg/m3 |

| Nunavut | Consolidation of Occupational Health and Safety Regulations | Cristobalite (respirable) : 0.05 mg/m3 Quartz (respirable): 0.05 mg/m3 Tripoli, as quartz: 0.1 mg/m3 |

| Yukon | Occupational Health Regulation | Quartz: 300 particles/mL Cristobalite: 150 particles/mL Tridymite: 150 particles/mL |

In the US, OSHA issued two new standards to protect workers form exposure to respirable crystalline silica-one for construction and the other for general industry and maritime. According to OSHA, the construction industry has approximately 2,000,000 workers exposed to respirable crystalline silica in over 600,000 workplaces in the United States.

In the OSHA guidance document, OSHA uses a benchmark 8-hour time weighted average exposure of 0.05mg/m3 of respirable silica dust as a point of reference in describing control measures utilized by the construction trades. (Short term exposure can be higher).

If your exposure is over 0.05 mg/m3 for an 8-hour TWA, you MUST take appropriate measure to protect the worker and surroundings.

OSHA notes that some organizations like NIOSH and ACHIG recommend even lower levels (0.025 as an 8-hour time weighted average).

Generally, Canadian regulations are comparable to the U.S regulations, but in the States, violations are expensive and heavy fines are given to breach of Silcia Regulation. Stricter enforcement in Canada is likely in the future.

The Employer’s Legal Responsibilities

In any workplace where respirators are necessary to protect the health of the employee, or whenever respirators are required by the employer, the employer must establish and implement a written respiratory protection program with worksite specific procedures and elements, including the selection of respirators, medical evaluations of employees, fit testing, proper usage, maintenance and care, cleaning and disinfecting, proper air quality/ quantity and training.

According to OSHA there are two ways to determine silica exposure levels:

A) Air monitoring or

B) Through identifying certain activities on the Table 1 of the Standard and complying with the dust control methods lists.

Luckily OSHA has already done some of the legwork for employers and identified procedures you need to put into place to ensure any silica dust levels remain with the PEL (permissible exposure limit).

How can you protect against Silica Dust?

Implementing a respiratory program according to OSHA’s PEL is a non-negotiable to properly protect employees from Silica dust exposure. Dentec Safety has been providing respiratory training, solutions and programs for over 18 years and are leaders in this field.

Keep scrolling for Dentec’s Respiratory recommendations to protect against Silica Dust.

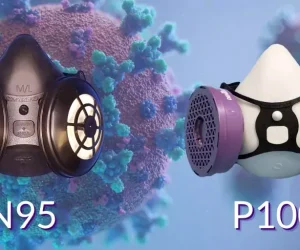

Good, Better, Best Respiratory Solutions According to OSHA’s Respiratory Protection Requirements.

GOOD

From 0.05 mg/m³ to .5 mg/m³ TWA 8 hours requires a NIOSH approved half-facepiece or disposable respirator equipped with an N, R, or P95 filter or higher with an Assigned Protection Factor (APF) 10.

Pros

- Thought to be economical.

- Lightweight.

- Universal fitting, some models available in multiple sizes.

- Exhalation valve model exhausts hot, moist air reducing heat build up and improving user comfort.

- Crush resistant shell design increases product life and improves comfort.

- Elastic straps sonically welded to the mask and no staples.

Cons

- Due to the possibility of working in high heat (ambient temperatures) and moisture due to wet tool usage, daily consumption may be high.

- Difficult to fit check when entering hazardous application.

- Will cause fogging on safety or prescription eyewear.

- Will cause nose bridge irritation.

- Will not fit well with ponytails or hair up in a bun.

- More expensive in the long run as you need to constantly replace.

- BIG Environmental Impact- create more waste.

BETTER

Comfort-Air Reusable N95 Half Mask Respirators

From 0.05 mg/m³ to .5 mg/m³ TWA 8 hours requires a NIOSH approved half-facepiece or disposable respirator equipped with an N, R, or P95 filter or higher with an Assigned Protection Factor (APF) 10.

Pros

- N95 filters protect against non-oil-based particulate aerosols and is the recommended choice of OSHA.

- Replaces disposable respirators.

- Variety of mask materials; Silicone is most comfortable, Thermoplastic (TPR) or Elastomeric rubber not as soft but less expensive.

- No hotter than wearing a disposable style respirator.

- Provides and airtight seal.

- Multiple sizes allows for better fit and protection.

- We offer protective assembly to attach filter to half & full-face mask, protects from dirt, misuse and extends filter life.

- Easy to fit check before entering hazard work area.

- Replacement parts,

- More sustainable, less waste.

- Economical due to reduced filter consumption.

Cons

- Requires cleaning and maintenance.

BEST

Comfort-Air Reusable Half Mask Diskit P100 Filter

Comfort-Air Reusable Half Mask Respirators P100 Cartridge

From 0.05 mg/m³ to 0.5 mg/m³ TWA 8 hours requires a NIOSH approved half-facepiece or disposable respirator equipped with an N, R, or P-95 filter or higher.

Pros

- P100 cartridge eliminates 99.97% of dust particle vs 95% for 95 rated filter.

- Offers greater protection versus N, R, P-95 rated filters.

- Replaces disposable respirators.

- No hotter than wearing a disposable style respirator.

- Provides an airtight seal.

- Multiple sizes allow for better fit and protection.

- Replace when breathing resistance occurs.

- Due to greater filter material area reduces loading resulting in reduced breathing resistance, extending filter life and reducing consumption costs.

- Cartridge case protects filter and extends filter life.

- Easy to fit check before entering hazard work area.

- Optional Prefilter protects P100 cartridge, extends life reduces breathing resistance and consumption costs.

- More sustainable, less waste.

- Cost effective in the long run when compared to disposables.

Cons

- Requires cleaning and maintenance.

ULTIMATE PROTECTION: IF YOU REQUIRE PROECTION ABOVE APF25

Comfort-Air Reusable Full Face Mask Respirators

From .5 mg/m³ to 2.5 mg/m³ TWA for 8 hours, requires a NIOSH approved full-facepiece respirator equipped with an N-, R-, or P-95 filter or higher with an Assigned Protection Factor (APF) of 25. (FULL FACE RESPIRATORS PROVIDE AN APF OF 50).

Pros

- New Special composite silicone offers superior comfort and value.

- Certified by NIOSH as a universal size, reduces inventory of multiple sizes.

- Optional filters:.

- The N95 filters has protective assembly to attach filter to full-face mask, protects from dirt, misuse and extends filter life.

- P100 cartridge eliminates 99.97% of dust particle vs 95% for 95 rated filter.

- Diskit P100 Pancake style filter provides P100 protection and is a more economical solution then standard P100 cartridge.

- P100 Cartridge with optional prefilter extends life reduces breathing resistance and consumption costs.

- Easy to fit check before entering hazard work area.

- Replacement parts.

- Polycarbonate fog resistant lens protects workers eye/face area.

- Protective lens cover prevents scratching.

- Economical due to reduced filter consumption.

- Less expensive than powered air purifying respirators.

- Option prescription lens frame.

- Less Environmental impact, less waste.

Cons

- Requires cleaning and maintenance.

To learn more about how to protect against Silica Dust and the different types of Respiratory Protection available check out our wide range of products and solutions here.

Dentec Safety is a leading manufacturer and distributor of safety products in the North America since 2004. Dentec Safety is dedicated to providing the highest quality safety products and solutions delivering enhanced value and comfort. Our expertise from decades of experience in Industrial Safety and our innovative design technologies have solidified us as thought leaders in the field. Protection and comfort are at the core of everything we do at Dentec. As a leading manufacturer of Safety Solutions, it is our mission to help organizations do the right thing, keep their employees safe and exceed Industry Health & Safety Standards.