The EN 388:2016 standard sets the guidelines for testing gloves against various mechanical risks, helping users understand and select the right gloves for their specific needs. This guide breaks down the key characteristics tested under EN 388:2016, along with the updated testing methods compared to the previous 2003 version.

Key Performance Tests in EN 388:2016

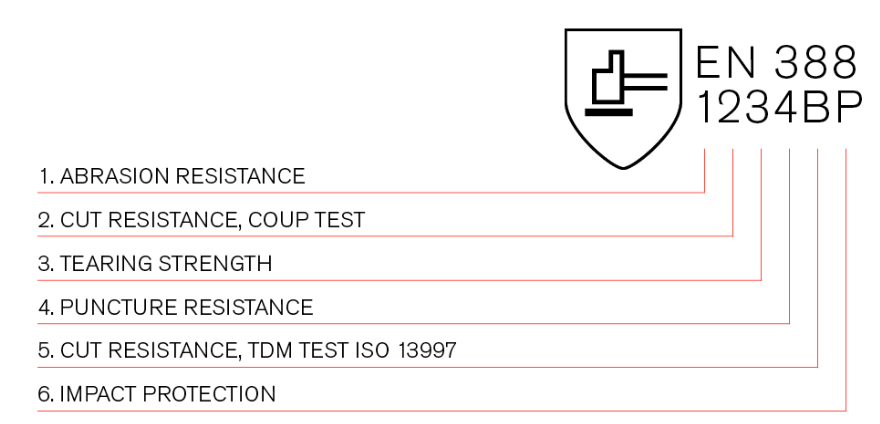

With EN 388:2016, gloves are rated based on resistance to abrasion, cutting, tearing, puncturing, and impact. These ratings are displayed alongside the EN 388 pictogram, which is followed by four numbers and one or two letters that indicate each glove’s level of performance.

EN 388:2016 Testing Categories Explained

- Abrasion Resistance

Gloves undergo abrasion testing with sandpaper under specific pressure to evaluate durability. A scale from 1 to 4 rates the glove, with a higher number indicating stronger resistance to wear and tear. - Cut Resistance (Coup Test)

To measure cut resistance, a blade moves across the glove material until it cuts through. Protection is rated from 1 to 5, with 5 offering the highest level of protection. If the material dulls the blade, an alternative TDM test (ISO 13997) is used instead (see #5). - Tearing Strength

This test measures the force needed to rip the glove material. Rated from 1 to 4, a higher number signifies greater tear resistance. - Puncture Resistance

This test determines the force required to puncture the glove with a pointed object. Ratings range from 1 to 4, with 4 representing the highest level of puncture protection. - Cut Resistance (TDM Test, ISO 13997)

If the Coup Test blade dulls during testing, the TDM test is used instead. This alternative cut test assesses the force needed for a blade to cut through the material over a 20mm length, with ratings from A to F (F being the highest protection level). - Impact Protection

If gloves provide impact protection, this is indicated by the letter “P” as the sixth character. If no “P” is displayed, the glove does not claim impact protection.

EN 388:2003 vs. EN 388:2016

The 2016 update to EN 388 introduced a few modifications in testing methods:

- Abrasion Test: Revised to include a new paper grid.

- Cut Resistance: Updated to better accommodate cut-resistant fibers.

- Impact Testing: Now included as an optional test.

Older gloves labeled under EN 388:2003 are still acceptable for use; the new standard simply changes testing methods rather than performance expectations.

Conclusion

EN 388:2016 provides clear guidelines on glove protection against mechanical hazards, ensuring you can select the appropriate gloves for tasks involving abrasion, cuts, tearing, punctures, and impact. Understanding these performance indicators helps you make informed choices to keep hands safe in challenging environments.